Wire rope inspection: The Ultimate Guide to Safety and Lifespan Offshore

Wire rope inspection is a crucial safety precaution taken in the maritime or offshore sector. Inspections help determine whether the ropes used for lifting, anchoring, and hauling heavy objects have wear, corrosion, or mechanical problems. Even the most stringent wire ropes without a permanent inspection might fall apart, causing an unsafe working environment, operating equipment malfunctions, and losing valuable time. Tabitha Offshore takes quality inspections on their wire rope seriously, and makes it a priority as an important aspect of operation, specifically, safety and efficiency in the offshore environments; your assets will work satisfactorily even in extreme conditions.

What is Wire Rope Inspection?

Wire rope inspection: A method that involves the systematic examination of wire rope to determine signs of deformation, wear, damage, and corrosion. Rope inspections guarantee the ropes are safe and serviceable in extreme working conditions, especially offshore, where the working environments are extreme and unfriendly.

It is not an optional procedure: regular inspections are enforced by safety standards, implying API, ISO, OSHA, and IMCA. Such inspections not only aid in adhering to the law but also prolong the service time of your equipment.

What Is the Importance of Wire Rope Inspection?

Failure to inspect the wire rope may have a disastrous effect. And that is why frequent and thorough checks are significant:

- Safety: A damaged rope could cause serious harm or possibly death.

- Cost-efficiency: The wear can be detected early, and thus, costly replacement or emergency repair will not be necessary.

- Compliance: The legal agencies dictate inspection and records regularly.

- Equipment life: Inspection keeps the winches, cranes, and pulleys under less pressure.

The kinds of Wire Rope Inspection Types

1. Visual Inspection

These obvious signs of harm sought by inspectors include:

- Broken wires

- Corrosion or rust

- Kinks/Bird caging

- Flattened areas and abrasion areas

- Pitting or cracking

- Periodic visual inspection should be done daily or every week.

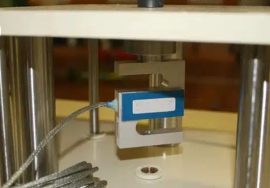

2. Magnetic Flux Leakage (MFL)

MFL finds internal cracks and corrosion that are not visible on the surface. This process has magnetic sensors that are used to identify concern areas.

3. Electromagnetic Testing (EMT)

As a means of checking the integrity of the rope, electromagnetic pulses sent by EMT can be used. It is more sensitive than MFL and perfect to use on ropes with high loads.

4. Tension and Dimensional checks

Inspectors also check the type, diameter and tension of the rope. Any reduction in grip size suggests a causing wear or an internal injury.

What to Detect in Inspection?

The following key areas will be covered in the general examination:

- Broken Wires: When you have over six broken wires in a single lay, then it is time to hang up the rope.

- Certification: Rust is fast under salt water. Check out pitting or dandruff-like strands.

- Deformation: Mechanical damage is indicated by bird caging, kinks, and crushed strands.

- Core Condition: Condition presence: presence of core protrusion or fiber core degradation.

- Lubrication: Cracks or dry areas could indicate the problem of poor lubrication, resulting in friction inside the machine.

What is the Frequency of Wire rope inspections?

The frequency of the inspection will depend on the attribute of the rope, the amount of certain load, and other conditions. Look at the general guideline hereunder.

- Normal operations – Weekly inspection

- Heavy loads or high importance application- Check every day

- Using cranes or pre-shot inspection for offshore drilling before shifts

- After abnormal conditions (such as overloads, shock-loading, or storms), check right away.

Best Practices of Offshore Wire Rope Inspection

The following are practices that Tabitha Offshore proposes:

- Train your staff members: Only trained individuals must inspect the wire ropes. Our professionals provide customized training based on the requirements of your crew.

- Use sufficient instruments: check carefully through the use of calipers, gauges, magnet testers, and visual instruments.

- Load test: Assuming that it is safe to apply, test the rope under load as a test of its performance. Twisting or sagging can be an indication of internal failure.

- Replacement in time: Do not wait until an absolutely failed component. Change ropes that meet or pass the discard standards.

Replacing a Wire Rope Once and for All

Once you start seeing any of the below, take the time to replace your wire rope:

- More than six lay-length broken wires

- Total pressure collapse or serious corrosion

- They decreased diameter by a margin of more than 10 percent.

- Kinking or flattening out

- Long span of burning exposure or chemicals

Selecting the right Inspection Partner

The inspectors need to perform a wire rope inspection skillfully, experienced, and understanding the offshore problems in depth. We have decades of experience in handling ropes, rope inspections, and rope certifications at Tabitha Offshore. We employ fully international protocols, and all the equipment we use is of industry standards, so as to ensure that your operation is safe and does not violate any industry standard.

Complementary services we offer:

- Report on detailed inspection

- Digital documentation

- Advice of an expert regarding rope replacement

- 24/ 7 offshore support

Frequently Asked Questions (FAQ) of Wire Rope Inspection

Q1. What is the use case of wire rope?

Ans: The inspection of wire ropes assists in detecting any damage, wear, or corrosion that could affect the rope. It guarantees safety, preserves equipment operability, and follows up industry codes such as API, OSHA, and ISO.

Q2. Who is eligible to examine wire ropes?

Ans: Approved people have to execute investigations of the wire rope. Such inspections conducted offshore like the one carried out by Tabitha offshore may usually require experts with adequate knowledge on marine and drilling conditions.

Q3. Does wire rope need to be lubricated?

Ans: It certainly will, lubrication minimizes internal friction, stops corrosion, and ensures long rope life. During the regular inspection, the inspectors have to look at dry or cracked surfaces.

Conclusion

Producing false-positive wire rope inspection reports. This is not only a safety precaution, but rather a mission-critical task on its way to preserving your crew, equipment, and bottom line. For the offshore drilling rigs, supply vessels, or construction platforms you are running, your wire ropes require care.

Enlist the services of Tabitha Offshore when you need a serious certification inspection. Safety and excellence are our main concerns, and that is why we are a reliable name in our offshore support.