Load Testing Equipment: Structural Safety in a Precise Way

There is no compromise when it comes to the safety required in a demanding offshore, marine-based and heavy industries. Load testing equipment is essential in the testing of strength and stability of all lifting parts, structures as well as equipment before actual application. At Tabitha Offshore we supply state of the art load testing services and equipment to upgrade to industry standards and to suit the client requirements.

Design and construct our load testing products are diverse and extend to everything: testing cranes, davits, and spreader beams, winches, lifeboats, and pad eyes. Whether you work in the offshore rig or in a port facility, load testing will make sure that your systems will operate under operational stresses and not fail.

What Is Load Testing Equipment?

Load testing equipment (using test tools, and specially constructed machines) help engineers to subject structures or mechanical systems to simulated loads and evaluate their integrity. The tools simulate actual environment conditions in real life, enabling engineers to detect any vulnerable points, fatigue, or structural deficiency.

Typical load testing tools include:

- Water Bags: Perfect to be used on cranes and lifeboats where they can apply well-regulated loads through the use of water-filled bags.

- Hydraulic Jacks and Cylinders: Often utilized in tension and compression tests applied on lifting machinery.

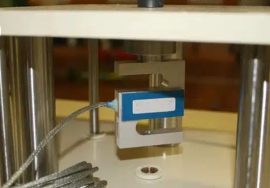

- Load Cells: A Form of high level accuracy sensors, which are used to determine the force or weight in a test.

- Test Weights: Iron or concrete weights which are used to represent working loads.

- Spreader Beams and Slings: They are the accessories that lead to the distribution of loads in a safe and distributed way.

The Need To Load Test?

Lack of adequate load test results is disastrous, and it may cause death and loss of property. This is why load testing should become a priority in any project:

1. Adverse Investigation International Standards

For equipment certification, organizations like ABS, DNV, and LEEA require load testing.

2. Mechanical Failures Prevention

Load testing discloses any weak points in the structure of the equipment prior to putting them on service.

3. Risk Mitigation

Early defect detection reduces repair costs, potential legal action, and downtime.

4. Operational Confidence

Both the management and the operators may rest easy knowing that the equipment is certified.

Tabitha Offshore Load Testing Capabilities

We offer complete load testing services in the offshore and industrial services in Tabitha Offshore. Our trained engineers also have the latest of state-of-the-art load testing equipment, which gives accurate and repeatable and traceable outputs.

The services that we offer are:

- Pad eye, hoist, crante, davits and life boat loading tests.

- lifting equipment and accessories proof load testing.

- Portable load testing kits and on-site/off-site testing are also available.

- Wireless load cell, data recorder, and digital load monitoring.

- Supportive test reports and third party certification.

Load testing equipment can also be supplied or rented out at our end allowing the client to be able to simultaneously conduct in-house tests whenever the need arises.

Our Load Tests Types

1. Static Loads Testing

Is used during a certain interval to apply constant force to check the behavior of equipment with steady loads.

2. Dynamic Load Testing

Requires variation of load during operation in order to mimic real time working conditions.

3. Proof Load Testing

Applies a specific load to a system to verify its structural soundness.

4. Destructive Testing

Research and development; this type of test uses equipment to the limit of failure to research performance and safety margins.

The Industries we serve

- Offshore Oil and gas

- Shipbuilding Marine

- Ports and Harbors

- Manufacturing Plants

We have a wide portfolio to work in different industries and we are able to offer the specific solution in accordance with the situation in the particular environment.

Load Testing Equipment – FAQs

Q1: How frequently should load tests be conducted?

Ans: There is an annual load testing by the professionals or by the standards provided by the manufacturers and control bodies. They might have to conduct more tests in scenarios of extreme usage.

Q2: Should I rent, or buy load testing equipment?

Ans: Buying would be cost-effective in case professionals conduct tests at multiple sites or on a regular basis. However, it is more efficient to hire the equipment from a certified company as Tabitha Offshore in order to use it sometimes.

Q3: Which are the standards in load testing?

Ans: Such standards as BS EN, ISO, LEEA, ABS, and DNV GL establish requirements on the procedure of load testing. We are a company that strictly operates in keeping up with these standards at Tabitha Offshore.

Q4: Is it feasible to do load testing remotely?

Ans: Yes. The services we provide include the portable load testing equipment and the expert technological craftsmen who are able to carry offshore tests out successfully and securely.

Conclusion

If an entity is interested in investing in good quality load testing equipment and services, then it is not only regulated but also an important safety measure. Here at the Tabitha Offshore, we understand the technical knowledge and apply the latest technology to give you safe, effective and compliant operations. In case you require onsite testing, equipment rental, and full-scale inspection services, we are on hand to provide your load testing requirements.